The MC engines had cam shaft control, which made it difficult to control fuel injection and exhaust valve actuation as desired. With ME engines, instead of cam shaft control, electronic control is used, allowing for more precise adjustments to fuel injection timing and rate, as well as exhaust valve timing and operation. This improved control results in several benefits, such as maintaining high fuel pressure under low load conditions, better adjustment of cylinder lubrication as needed, and improved engine balance and load control.

Electronic control manages not only fuel injection and exhaust valve actuation but also governor functions, cylinder lubrication, start and reversing sequences, starting air valves, and auxiliary blowers. To handle such comprehensive control, various controllers are required. Instead of using a different controller for each function, similar electronic controllers are utilized with software modifications for different purposes. These controllers are referred to as multipurpose controllers.

In ME engines, there are ME-B and ME-C models. The ME-B model still includes a cam shaft. Although it uses electronic control for fuel injection, cylinder lubrication, and governor functions, it handles the start and reversing sequence and exhaust valve actuation through cam control.

MPCs (Multipurpose Controllers) are used in control systems as follows:

- EICU – Engine Interface Control Unit

- ECU – Engine Control Unit

- CCU – Cylinder Control Unit

- ACU – Auxiliary Control Unit

These four units are MPCs used in the engine control systems of ME engines. Depending on the engine type, additional MPC units may be used:

- CWCU – Cooling Water Control Unit

- SCU – Scavenging Control Unit

Additionally, for IMO Tier III engines, MPCs are also used for NOx reduction through Exhaust Gas Recirculation (EGR) and Selective Catalyst Reactor (SCR). I will explain these MPCs according to their functions next.

MPC Basic Structure

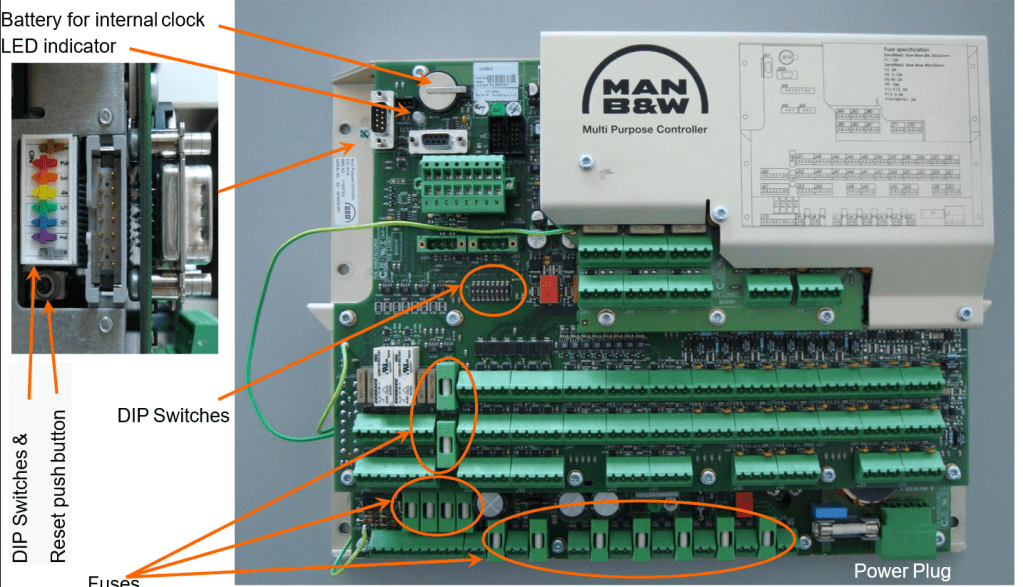

An MPC (Multipurpose Controller) is a controller that can be adapted for different engine control system applications by changing its program, as its name suggests. The hardware components of MPCs are similar across different models. MPCs use the Motorola 68332 as the main processor, which is known to have been initially used in automotive engines. The program is stored in a non-volatile Flash PROM, and it is designed to be downloadable via a wired bus network.

Each MPC has an ID key (dongle key) that stores information such as the MPC card’s location, function, and address. When a new MPC card is installed, the ID key provides the necessary information about its address and function.

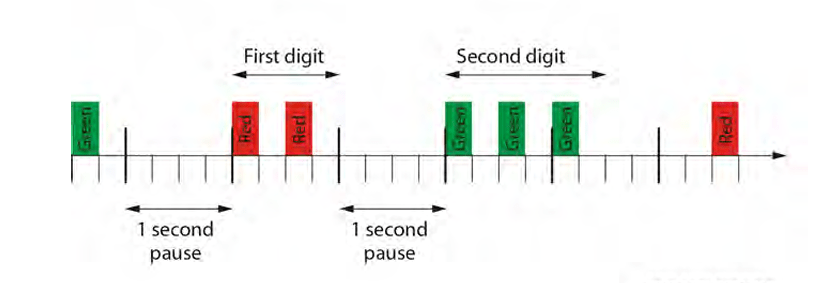

The status of the MPC card can be monitored through LED indicators on the card. A green LED indicates that the card is functioning normally. A yellow LED signals conditions such as program initialization or the presence of data issues. A red LED indicates that the card is not functioning at all. The LED lights up in different patterns to indicate the card’s status.

To reset the MPC card, there is a reset button on the card itself. Resetting an MPC with redundancy, such as the EICU, will not affect engine operation. However, resetting an MPC without redundancy, such as the CCU or ACU, could cause a slowdown in engine operation, so caution is advised.

On the side of the MPC card, there is a multicolor DIP switch used to differentiate and set various functions. On the top of the card, there are two black DIP switches labeled S1. The multicolor DIP switch is used for program controller functions such as enabling/disabling power and setting the watchdog timer. By default, the start and end positions of the switch should always be in the OFF position, while the remaining positions should be in the ON position.

DIP switch S1 is used for programming the ID key. I will provide further details on this later.

The MPC card also contains a coil battery for backup power supply and internal clock functions. If you use the MPC card without this battery, it may reset automatically. If the battery is low and needs replacement, it is best to power off the MPC card and replace the battery during a safe condition when maneuvering is not taking place. This is because replacing the battery may cause the MPC card to reset and restart.

One variant of the MPC card is the MPC-10. It is considered more compact and cost-effective compared to the MPC. The MPC-10 is often used for Cylinder Control Units (CCU). While the MPC has 55 external connectors, the MPC-10 has only 22. Unlike the MPC, the MPC-10 features a sealed design.

In systems like the Cylinder Control Unit (CCU) and Auxiliary Control Unit (ACU), amplifier units are often connected to ensure proper load drive performance. Sometimes, the amplifier unit is mounted inside the cabinet along with the MPC, while in other cases, it is placed underneath the MPC card. Some versions of the MPC even have built-in amplification.

Main Operating Panel (MOP)

The Main Operating Panel (MOP) serves as the primary information interface for the Engine Operation System and also functions as a computer with Engine Control System software. The MOP connects to MPCs through the control network, presenting the received data to the operator and allowing for effective monitoring and control. There are two types of MOP: MOP A and MOP B. For Tier III engines, which include additional components such as Selective Catalyst Reactor (SCR) or Exhaust Gas Recirculation (EGR), an additional MOP is provided.

Through the MOP, operators can view alarm information, process parameters, the status of MPC cards, and real-time input/output values. Information and troubleshooting guides are available for each alarm. MPC cards feature built-in insulation monitoring, and the MOP displays the insulation resistance status of MPC cards, sensor values, and which sensors are connected to which MPCs. The software interface of the MOP is designed to be simple and user-friendly for quick and easy navigation.

References

1) Hyundai-Man B&W Diesel Engine Main Engine Manual Volume II

2) MAN Diesel PrimeServ Academy

(This overview of ME Engine Control Systems is intended solely for educational purposes and knowledge sharing. It is not designed for commercial publication or professional use. The information provided aims to offer a general introduction to ME Engine Control Systems for those unfamiliar with the topic.

Please be aware that this overview is based on specific ME engines encountered and reflects current technology as of the date of writing. Due to the evolving nature of technology, there may be gaps, discrepancies, or inaccuracies in the information presented.

For the most accurate and up-to-date information, further research and consultation with industry experts are recommended. Corrections, additional insights, and feedback from the community are welcome to enhance the accuracy and usefulness of this material.)

Leave a comment