EX in this context refers to explosion-proof or Ex-proof devices, not to the historical narratives. These devices are designed to prevent explosions or avoid ignition. In simpler terms, an Ex-proof device is one that ensures no explosion will occur and prevents ignition. Common examples include motors and lighting. If you see “Ex” on a device’s nameplate, it indicates that the device is explosion-proof. The letters following “Ex” detail the protection level of the device.

Certification for Ex-proof Devices

————————————–

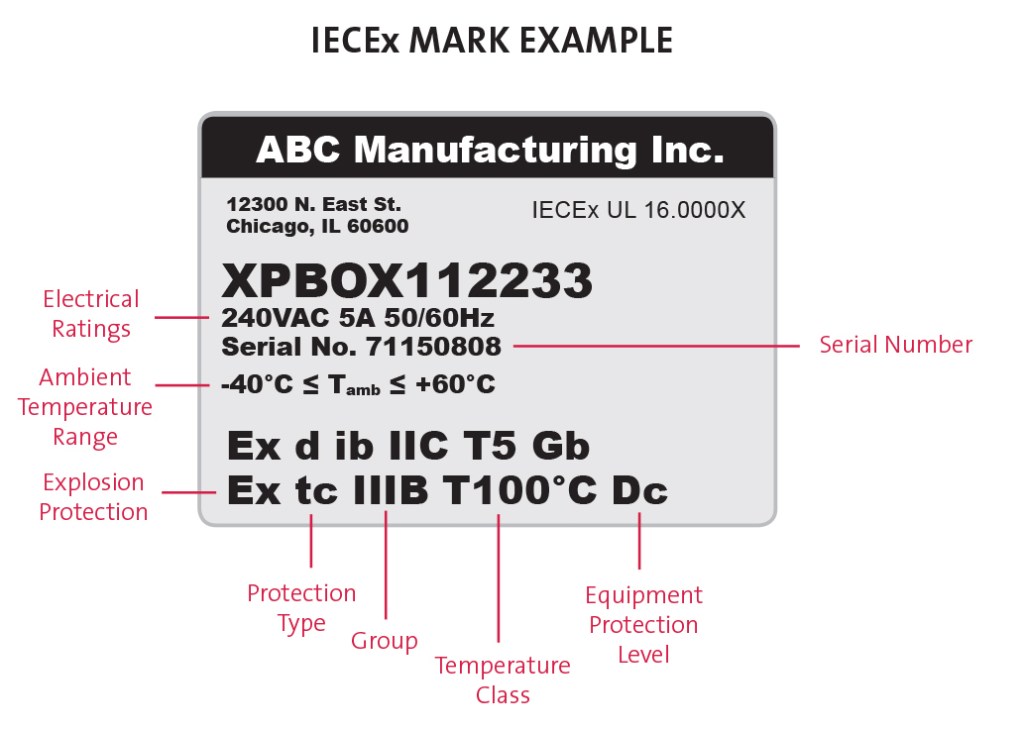

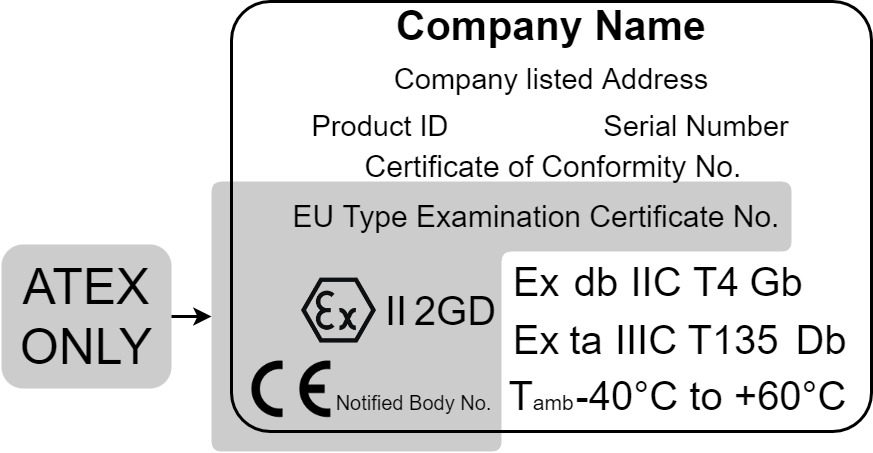

Certification for Ex-proof devices is provided by ATEX and IECEx. ATEX, which stands for ATmosphères EXplosibles, is an EU standard that often includes the CE mark. IECEx, the International Electrotechnical Commission Explosive, is governed by the International Electrotechnical Commission’s standards (IEC). For general users, it’s important to focus on the marking on the nameplate as it indicates the certification standards and regulations.

1. Protection Concept

————————

The protection concept explains how a device controls ignition if it occurs. The letters following “Ex” indicate the type of protection:

o (Oil Immersion): The ignition source is immersed in oil, which controls it.

p (Pressurized): The ignition source is kept under pressure with inert gas to control it.

q (Powder Filled): The ignition source is immersed in sand or quartz to control it.

d (Explosion Proof): The enclosure prevents ignition from escaping to the outside, making it flameproof.

e (Increased Safety): Designed to prevent any potential ignition sources like arcs, sparks, or hot surfaces.

ia/ib (Intrinsic Safety): Common on onboard equipment, it controls temperature and energy to prevent ignition.

m (Encapsulation): The ignition source is encapsulated in resin to control it.

op is (Optical Radiation): Manages optical radiation to ensure it does not escape the enclosure.

2. Hazardous Area

———————

This specifies the type of hazardous area where the device can be used. It is indicated by a combination of English letters and numbers:

G (Gas and Vapour) and D (Dust) are used to denote the type of propellant.

Zones for Gas and Vapour: 0, 1, 2

Zones for Dust: 20, 21, 22

Zone 0/20 (Level 1): Areas where explosive atmospheres are always or frequently present.

Zone 1/21 (Level 2): Areas where explosive atmospheres are occasionally present.

Zone 2/22 (Level 3): Areas where explosive atmospheres are not expected but may occur.

3. Electrical Equipment Group

———————————

This indicates the environment in which the electrical equipment can be used, denoted by Roman numerals and letters:

I: For mines.

II: For explosive gas atmospheres.

IIA: Environments with gases like propane.

IIB: Environments with gases like ethylene.

IIC: Environments with gases like acetylene or hydrogen.

4. Temperature Classes

————————–

Indicates the temperature range within which the equipment can safely operate:

T1 – 450°C

T2 – 300°C

T3 – 200°C

T4 – 135°C

T5 – 100°C

T6 – 85°C

5. Equipment Protection Level (EPL)

—————————————–

Defined by IEC, this classifies the level of protection according to the type of explosive atmosphere:

a: Very high protection, requiring two faults to cause ignition.

b: High protection, requiring a single fault condition to cause ignition.

c: Standard protection, needing extra measures to prevent ignition.

For example, a device marked as II 1 G Ex ia op is IIC T4 Ga indicates:

II: Equipment Group for Gas and Vapour.

1 G: Very High Hazardous Gas Area.

Ex ia op is: Intrinsically safe and with optical radiation protection.

IIC: Suitable for environments with acetylene or hydrogen.

T4: Operates safely up to 135°C.

Ga: Very high protection level in explosive gas atmospheres.

For further detailed regulations and information, you can refer to IEC’s official website (www.iecex.com) and additional resources like:

1. http://www.e2s.com/gui…/protection-concepts-iecex-and-atex

Leave a comment