Cylinder Lubricator

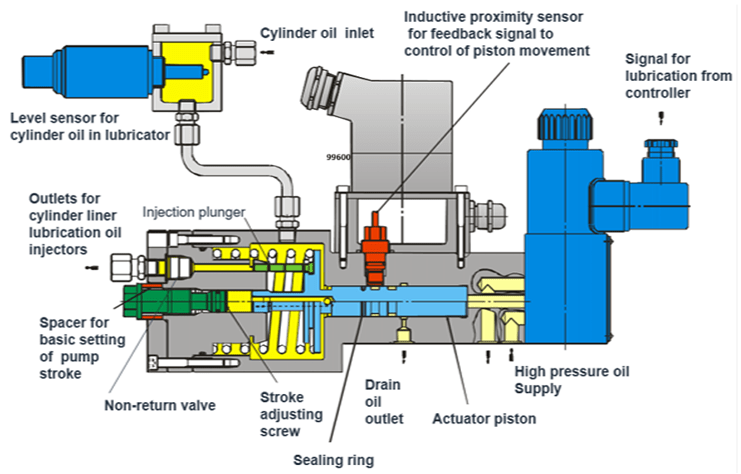

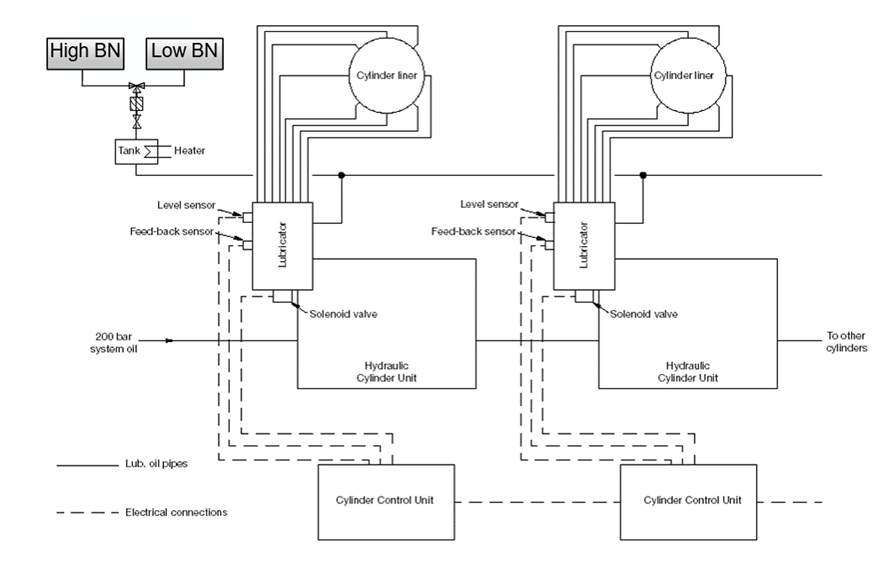

The cylinder lubricator is mounted on the distribution block of the hydraulic cylinder unit. It adjusts the lubrication oil flow based on the cylinder lubrication rate sent by the CCU, controlling the on/off cycles and amount of lubrication oil delivered to the cylinder units. The lubricator operates using the system’s hydraulic oil. Hydraulic pressure acts on the lubricator’s spring, pushing lubrication oil through an injector to the cylinders. An inductive proximity sensor is used to provide feedback on whether the lubricator is functioning.

Unlike the older MC engine systems that used the Alpha lubricator, which controlled lubrication with cylinder oil alone, the current systems use hydraulic oil for operating the lubricator. Previously, if cylinder oil did not reach the lubricator, it would not function, and cylinder lubrication would be absent. This setup allowed the system to detect if lubrication was missing if feedback was not received from the lubricator.

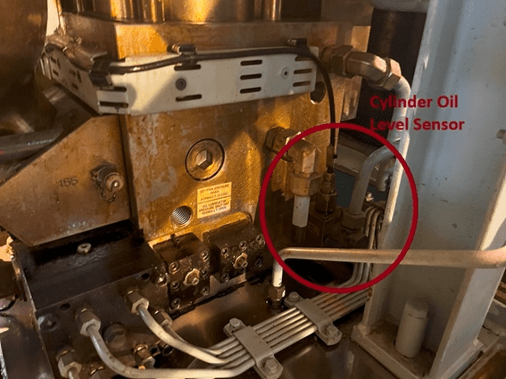

In the new systems, hydraulic pressure ensures the lubricator operates, and the feedback sensor confirms its activity. However, if lubrication oil does not enter the lubricator, the system might mistakenly think the lubricator is working, but the cylinder lubrication oil might not be reaching the cylinders. To address this, a small tank with a level switch is installed at the lubricator’s inlet to detect whether cylinder lubrication oil is being supplied.

As previously mentioned regarding the MPCs, if the CCU fails, it will no longer send commands to the lubricator, resulting in a situation where cylinder lubrication is not available. In such a case, you must connect the emergency lubricator cable to provide a random feed to the lubricator through either ECU A or ECU B’s J52.

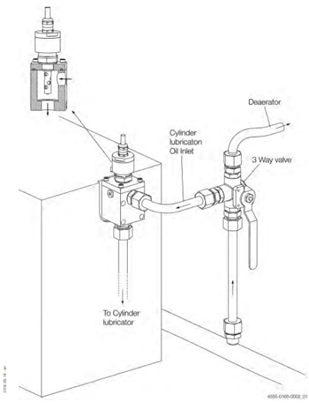

One of the purposes of cylinder lubrication is to neutralize sulfuric acid that forms due to sulfur in the fuel. To achieve this, the lubrication is adjusted depending on the type of fuel used, employing either Low BN (base number) or High BN cylinder oil. For MGO (Marine Gas Oil), Low BN cylinder oil is used, while for HFO (Heavy Fuel Oil), High BN cylinder oil is utilized. Some ME engines are equipped with systems such as the Automatic Cylinder Oil Switch (ACOS) and Automated Cylinder Oil Mixing (ACOM) for this purpose.

The Engine Control System calculates the cylinder lubricating feed rate based on the sulfur content of the fuel. The ACOS system switches to Low BN oil when the feed rate is 1g/kWh or below, and to High BN oil when it is above 1g/kWh, using a 3-way valve. If a system failure occurs, the 3-way valve will default to the High BN oil line. The ACOM system, unlike ACOS, does not simply switch lines but mixes the two types of cylinder oil to achieve the desired BN level. As of now, I have not yet encountered these two systems in practice.

References

1) Hyundai-Man B&W Diesel Engine Main Engine Manual Volume II

2) MAN Diesel PrimeServ Academy

(This overview of ME Engine Control Systems is intended solely for educational purposes and knowledge sharing. It is not designed for commercial publication or professional use. The information provided aims to offer a general introduction to ME Engine Control Systems for those unfamiliar with the topic.

Please be aware that this overview is based on specific ME engines encountered and reflects current technology as of the date of writing. Due to the evolving nature of technology, there may be gaps, discrepancies, or inaccuracies in the information presented.

For the most accurate and up-to-date information, further research and consultation with industry experts are recommended. Corrections, additional insights, and feedback from the community are welcome to enhance the accuracy and usefulness of this material.)

Leave a comment