The Linked Ship-Shore ESD that I am referring to is the Ship-Shore-Linked SSL Emergency Shut Down System (SSL ESD) used on gas tankers. I have met with this system on gas tankers. However, I have not encountered it in oil or chemical tankers. Some terminals provide extension pendants for emergency stops, which I have experienced before.

The ESD system is designed to immediately halt cargo operations in an emergency, preventing further incidents and ensuring that the operation is brought to a safe static condition. This system allows for the activation of the emergency stop signal from either the ship or the shore, ensuring that both parties can stop the operation without delay in an emergency situation.

According to the IGC Code requirements, gas tankers are required to be equipped with ESD systems. SIGTTO (Society of International Gas Tanker and Terminal Operators) has provided additional recommendations regarding arrangements and requirements for ship-shore links.

ESD systems can be categorized into Manual Trip Points and Automatic Trip Points. Manual Trip Points require human activation, while Automatic Trip Points include:

– Blackout/power failure of the ship

– Fusible plugs

– Cargo Tank Very High Level Alarm

– Tank Low Pressure

– Hold/Cargo tank differential Pressure

– Low cargo valves hydraulic pressure

– Low control air pressure

– Fire extinguisher system released

When an ESD is triggered, valves in the open condition will close, and cargo pumps, compressors, and inert gas generators will be stopped. On the shore side, relevant cargo operation machinery and valves will also be stopped. To prevent pressure surges during valve closures, SIGTTO recommends that ship ESD valves should have a traveling time of 25-30 seconds, and terminal valves should have 10-15 seconds for loading and 30-60 seconds for discharging.

SIGTTO has recommended a two-level ESD system: ESD1 and ESD2. ESD1 involves stopping cargo operation by closing valves and pumps, while ESD2 activates the Emergency Release System (ERS) and disconnects the terminal’s transfer arm.

Emergency stop signals can be transmitted via electric, fiber optic, radio telemetry, and pneumatic links in ship-shore connections. Pneumatic systems are less commonly used due to their maintenance needs and susceptibility to temperature and moisture-related errors. Radio telemetry is also less common due to varying national regulations, difficulties in standardization, and potential radio interference.

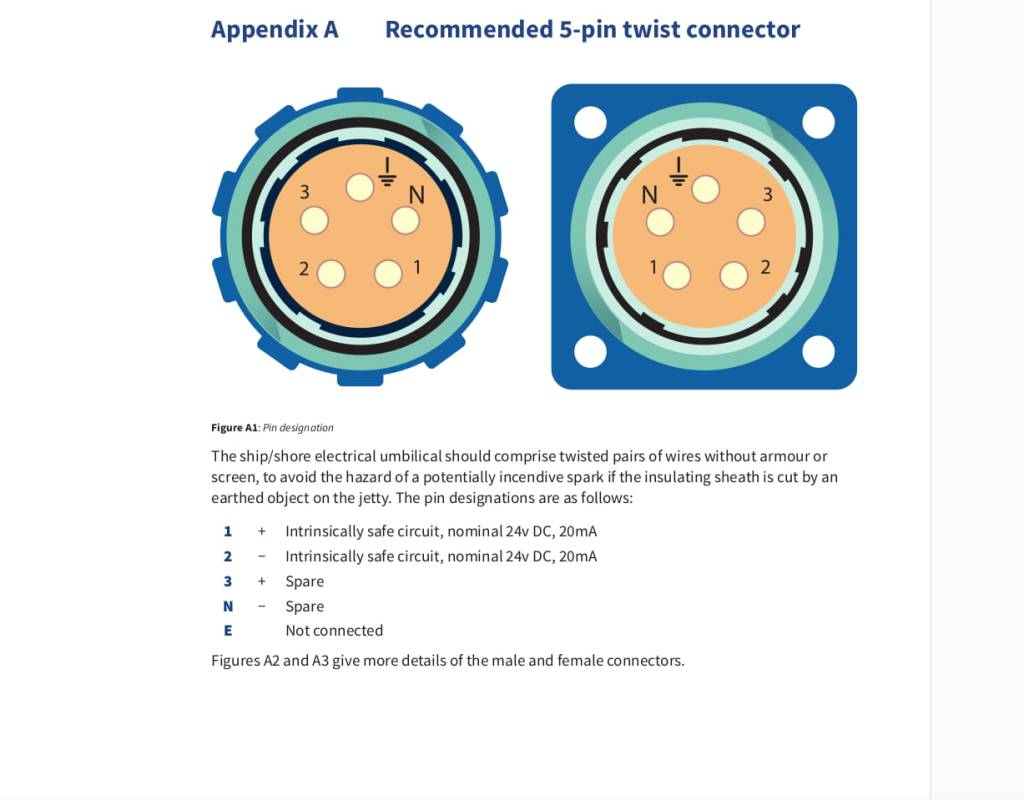

Currently, there are no specific standards for which type of link or connection should be used, which is noted as a significant drawback in the current liquefied gas carrier ESD systems. The North P&I Club/NorthStandard has highlighted this as a major weakness. OCIMF & CDI have suggested that oil and chemical tankers should also be equipped with ESD link systems, recommending the use of a 5-pin twist connector.

SIGTTO has recommended using fiber optic 6-pin, electric 37-pin, electric 6-pin, and electric 5-pin connectors for ESD links. Fiber optic and electric 37-pin are used for emergency stop signals as well as ship-shore communication, including hot line telephones and Ethernet links. These two types are more commonly found on LNG vessels, while LPG vessels typically use electric 5-pin and electric 6-pin connectors.

On the vessel I am currently on, an electric 6-pin connector is used. However, there have been instances where pin sizes in connectors with the same pin count differ, making it challenging to find compatible replacements.

—

Now, looking at the ESD system from the perspective of an ETO (Electrical Technical Officer), my vessel uses an electric 6-pin connection for the Ship-Shore ESD Link, specifically the MTL 901. The main PLC of the cargo control system is connected to the MTL 901 ship-shore link ESD controller. Emergency stop push buttons located in various areas such as the cargo manifold, cargo compressor room, CCR, and bridge are also integrated into the PLC. Signals like blackout and fire alarms are received by the PLC.

In the diagram, SIG 06 is the Ship-Shore Link ESD control box, while SG11 and SG10 are junction boxes located near the manifold. LTS2 is the cabinet for the Cargo Monitoring System, and it is connected to the Emergency Stops, the Valve Remote Control System, and the ESD Link

Additionally, fusible plugs are installed in the pneumatic line, with air pressure maintained at 7 bar. When the temperature reaches between 98 to 104°C, the fusible plug will open, causing a drop in air pressure in the pipe. At this point, the pressure switch sends an emergency stop signal to the main PLC. The main PLC then sends trip signals to close the emergency shutdown valves and stop the cargo compressors, cargo pumps, and inert gas generator.

As previously mentioned, the MTL 901 ship-shore linked ESD system processes the emergency stop signal through the main PLC and sends it to the shore side via the ship-shore linked wire. This setup allows the shore side to immediately stop the relevant machinery and valves on the ship. Similarly, the shore side can also stop the ship’s machinery and valves.

However, as previously noted, if the ESD-linked connection on the vessel does not match that of the terminal, the linked ESD system cannot be used. In such cases, only emergency stop signals via extension pendants can be provided, which requires manual intervention to activate the stop function. Although SIGTTO does not support the use of pendants, the lack of a standardized solution means that using extension pendants is currently necessary. This limitation means that the full functionality of the ship-shore linked ESD system cannot be utilized, and manual intervention is required to send emergency stop signals between the ship and the terminal.

What I have shared is based on the ESD system I am familiar with and the information I have read. There may be additional details or corrections needed. Please point out any necessary additions or corrections.

—

**References:**

1. SIGTTO. 2021. ESD Systems – Recommendations for Emergency Shutdown and Related Safety Systems, Second Edition.

2. OCIMF & CDI. 2017. Linked Ship/Shore Emergency Shutdown Systems for Oil and Chemical Transfers.

3. Rod Maclennan. 2018. Safe Shutdown for Tankers. Northstandard Articles.

Leave a comment