I’ve encountered issues with ACBs not turning ON or OFF about four times. Out of those, only once was it because the closing coil was broken, which prevented the ACB from turning ON. The rest of the times, it was due to the UVT controller.

Before talking about it, let me briefly explain what I know about ACBs. I’ve only worked with 440V systems on ships, so I’ll focus on ACBs.

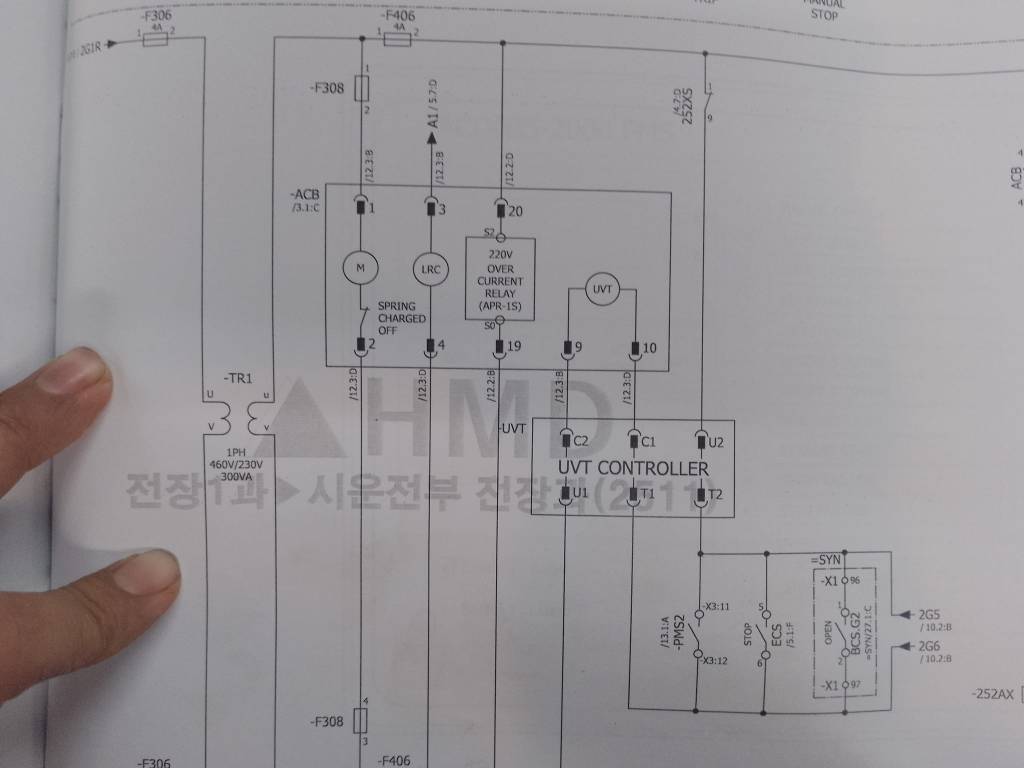

If I focus on the electrical aspects of the ACB without discussing the mechanisms, I can break it down into three parts: the UVT coil, the Shunt Trip, and the Closing Coil.

- Closing Coil: This coil is responsible for closing the breaker when the ACB’s spring is charged.

- Shunt Trip: This works in conjunction with a built-in Over Current Relay (OCL). If there is an abnormal current condition, the OCL activates the Shunt Trip, which causes the breaker to trip.

- UVT Coil: This coil protects against under-voltage conditions. It prevents the breaker from closing if the voltage is below a certain level and opens the breaker if the voltage drops too low. The UVT controller manages the UVT coil by energizing it when an under-voltage condition is detected.

If the breaker is opened by the Power Management System or manually, a signal is sent to the UVT controller. From there, it cuts power to the UVT coil and opens the breaker.

The UVT controller can be mounted next to the ACB body, and there are also compact versions. There may be slight differences depending on the maker, but generally, this is the concept I remember.

What can go wrong with the UVT controller?

There are two main issues that can cause the UVT controller to fail. One is when it cannot provide power to the UVT coil, and the other is when it is continuously supplying power.

If the UVT coil is not getting power, the ACB cannot close. So, if the ACB isn’t closing, you should check whether the rated voltage and frequency are present, and then check the input and output voltages of the UVT controller. The UVT controller’s input can be either 440V AC or 220V AC, so be careful when replacing it.

The output goes to the UVT coil and is a DC voltage. If there is input voltage but no output, it’s a clear sign that the UVT controller has failed. In this case, you can easily identify the problem without needing to draw out the ACB.

Another issue that can occur is when the ACB won’t turn OFF.

If you de-synchronize and the ACB still won’t turn OFF, reduce the generator load as much as possible and press the OFF push button on the ACB. After that, you can test the UVT controller by supplying it with the rated voltage. If the rated voltage is present and the coil is receiving output, you should short the Trip contact (NO) and check if the coil supply continues to output.

If the coil supply is still active when you short or close it, then the UVT controller has likely failed. This means that even if the PMS has commanded it to turn OFF, the UVT coil is still receiving power, which keeps the ACB ON.

What to do if the UVT controller fails?

The UVT controller is very important, so many ships keep spare parts and include them in their critical spare list.

Whenever you board a ship, check if the spare is available; if not, you should order one.

If there is no spare available, modifications can be made. In the picture, you can see a circuit I modified when the ACB wouldn’t turn OFF. When the ACB receives an open signal, a relay is energized, cutting the UVT coil supply through its NC contact.

One thing to keep in mind is that some companies allow this type of modification, while others require notifying the office through Chief Engineer. I always send a picture via email to the CE, and he ask for confirmation from the office.

Looking at the pictures will help you understand better.

Kyaw Soe Aung

25 May 2022, Atlantic Ocean

Leave a comment