It’s essential to regularly clean and inspect the magnetic contactors of motors that frequently start and stop. This routine maintenance helps prevent issues caused by arcing during contact engagement and disengagement. If contacts weld together due to arcing, it can lead to single phasing of the motor, resulting in significant losses.

When a motor experiences single phasing, the connected phases draw more current to maintain the designated power, causing overheating. If single phasing occurs due to a broken electric wire or a loose terminal, the overcurrent relay can detect this and cut off the coil supply voltage of the magnetic contactor, thus disconnecting the motor power for protection.

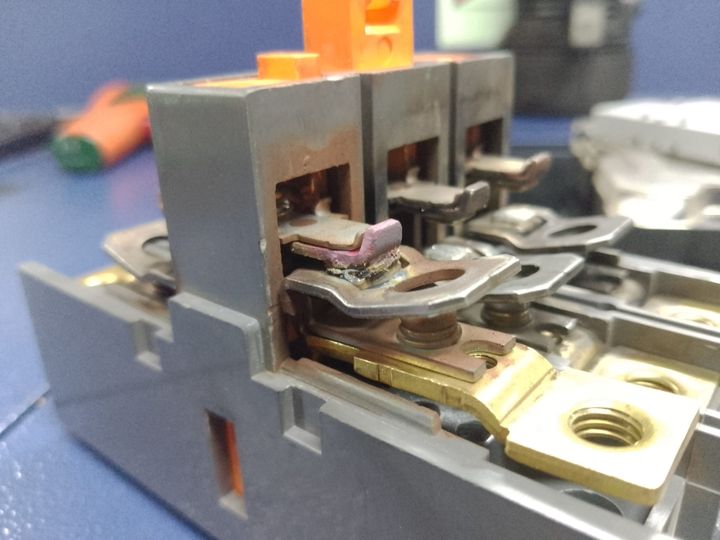

However, if contacts weld together due to arcing, the overcurrent relay cannot provide protection. When the magnetic contactor attempts to open, the welded contacts will remain stuck, while the other contacts will separate. This condition leads to single phasing, where the motor coil draws excessive current, which the overcurrent relay may detect, but since the contactor’s contacts are welded, the motor will continue to operate under single phasing.

At this point, the only remaining safeguard is the main breaker. However, based on its trip curve, the breaker may not trip immediately for single phasing, potentially allowing this condition to persist for an extended period. Eventually, the motor’s coils will draw excessive current, leading to overheating, insulation failure, and possible coil-to-coil short circuits, which could eventually cause the breaker to trip.

Once the motor has overheated, it may sustain irreparable damage, and there will be no opportunity to prevent the failure.

To address the initial question, arcing can create uneven surfaces on the contacts, leading to welding over time. Therefore, it is vital to maintain regular cleaning and inspection of the contacts. If the surfaces become uneven, they can be gently sanded with fine sandpaper to restore proper contact.

The photo depicts the main air compressor on my vessel. Initially, I received a low insulation alarm, and by the time I returned to the engine room, the motor had already burned out—this occurred in just four minutes.

Regular maintenance can help prevent these significant issues.

Kyaw Soe Aung

May 25, 2022 , New York, USA.

Leave a comment