For experienced ETOs and marine engineers, what I am sharing here may seem simple. But for junior ETOs and engineers who are just starting, these things can be hard to understand. I want to help those new to the job by sharing what I have learned.

From my real work experience as an ETO and working with marine engineers, I want to share some thoughts. If this helps younger or new colleagues even a little, I will be happy.

Today, I want to talk a little about the AMS (Alarm Monitoring System) — especially the Kongsberg K-Chief 600 Cargo Monitoring System, which I have used onboard ships.

When it comes to maritime industrial automation, what I have seen is only the tip of the iceberg. The full system is much bigger and more complex than what I have worked with. I have not worked on every part, but this K-Chief system gave me good experience.

Systems like AMS/IAS (Integrated Automation System) are very important on ships. Even though I only know some parts, this is a good start to learn more.

AMS/IAS systems may look different depending on the manufacturer, but they work in similar ways. If you know a little about instrumentation and can read circuit diagrams, you can understand and work with systems like the K-Chief 600.

—————————————————————————————–

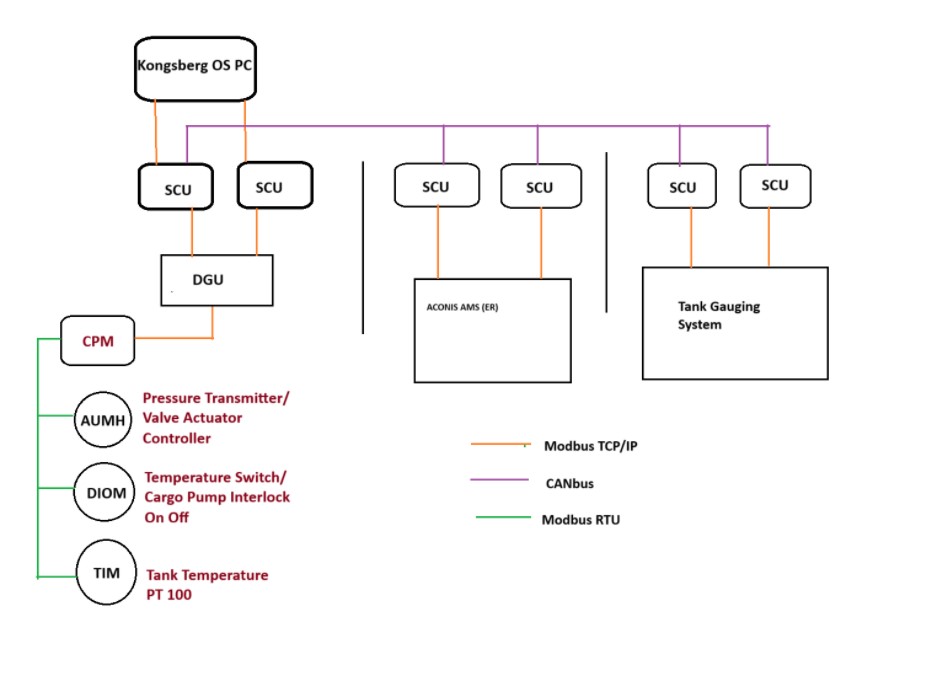

In our vessel, the engine room system is a Hyundai ACONIS alarm system, and the cargo monitoring system we use is the Kongsberg K-Chief 600.

The K-Chief system is made up of several modules that work together to monitor cargo. Let me explain some basic parts.

The cargo monitoring system uses sensors, transmitters, valves, motors, and pumps located on the deck and in the cargo tanks.

RTD sensors use resistors to measure temperature, and transducers send signals as 4-20 mA current to the system.

The K-Chief 600 receives these signals and processes them through input modules:

- AI (Analog Input) modules for analog signals

- DI (Digital Input) modules for digital signals

- Sometimes, Temperature Input modules are used for RTD PT 100 sensors.

On the output side, the system has analog outputs and digital outputs to control devices.

The K-Chief system collects and records data, allowing monitoring and control.

This setup is not only for K-Chief but also works closely with the Hyundai ACONIS AMS system for alarm monitoring.

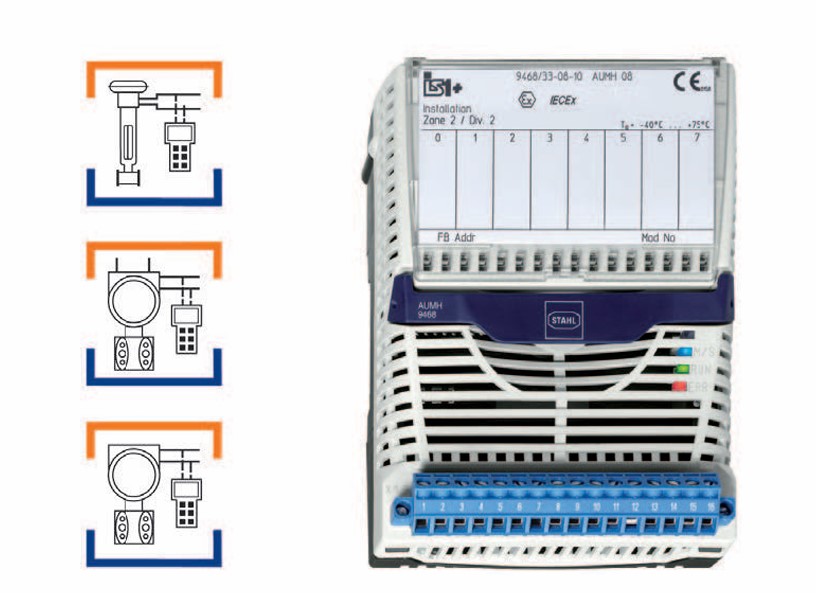

AUMH (Analog Universal Module HART)

In our system, the STAHL AUMH module is used to handle analog signal inputs and outputs — not the Kongsberg module. This module is designed for use in hazardous areas and is commonly found in systems that are not fully Kongsberg-based.

This module is responsible for both analog input and output signals in hazardous zones. In some systems, input and output modules are separate, but in the AUMH module, both input and output functions are included in one unit.

For example:

- A pressure transducer sends a 4–20 mA analog signal as an input.

- The output signal may go to a valve positioner, also as a 4–20 mA signal.

Since this system is used in hazardous areas, the Zener barrier is built into the AUMH module itself. This built-in protection helps ensure safe signal transmission without needing a separate external Zener barrier.

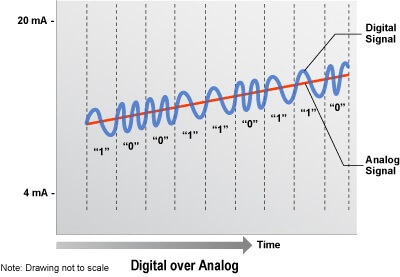

HART Signal in 4–20 mA Analog Loop (STAHL AUMH Module)

The STAHL AUMH module, which handles 4–20 mA analog input/output signals, also supports HART communication.

HART stands for Highway Addressable Remote Transducer. To explain it simply, HART works like a Walkie-Talkie system between the control system and the transmitter (transducer). While the 4–20 mA signal sends one-way analog data (e.g., temperature), HART enables two-way digital communication over the same wires.

Example:

A temperature transducer sends a 4–20 mA signal to the control system:

- Let’s say it sends 70°C as an analog signal.

- That signal only flows one way — from the transducer to the control system.

But with HART, the control system can also:

- Request or read the measuring range

- Get the transmitter ID

- Check for device errors

- And read other internal data — without interrupting the analog signal

How HART Works:

HART uses Frequency Shift Keying (FSK) to send digital signals on top of the 4–20 mA analog current:

- 1200 Hz = Digital “1”

- 2200 Hz = Digital “0”

This digital signal is “superimposed” on the analog loop. The analog and digital signals do not interfere with each other, which makes HART very useful in industrial systems — especially in hazardous areas where fewer cables are better.

DIOM – Digital Input Output Module

This module handles digital input and output signals. In many other systems, Digital Input (DI) and Digital Output (DO) are usually handled by separate modules. But in this case, the STAHL DIOM module supports both input and output in a single module.

So, the DIOM module is capable of handling digital signals coming in (input) and going out (output) all in one — which makes it a compact and efficient choice.

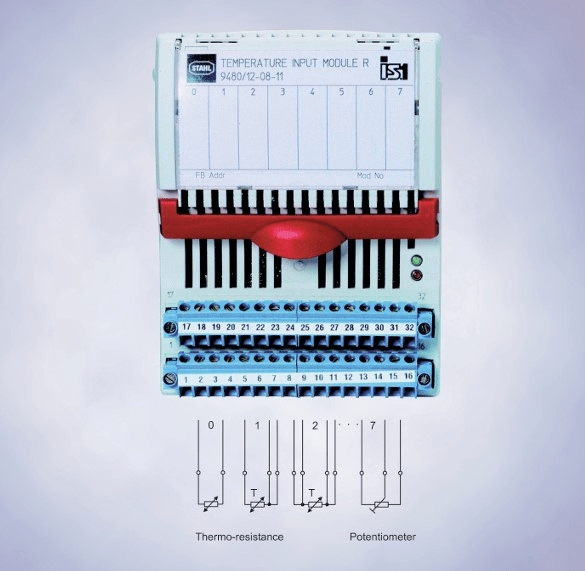

TIM – Temperature Input Module

This module takes resistance values from PT100 or other RTD temperature sensors as its input.

The AUMH, DIOM, and TIM modules discussed earlier all look very similar. Their nameplates and the types of input and output signals they handle are almost the same.

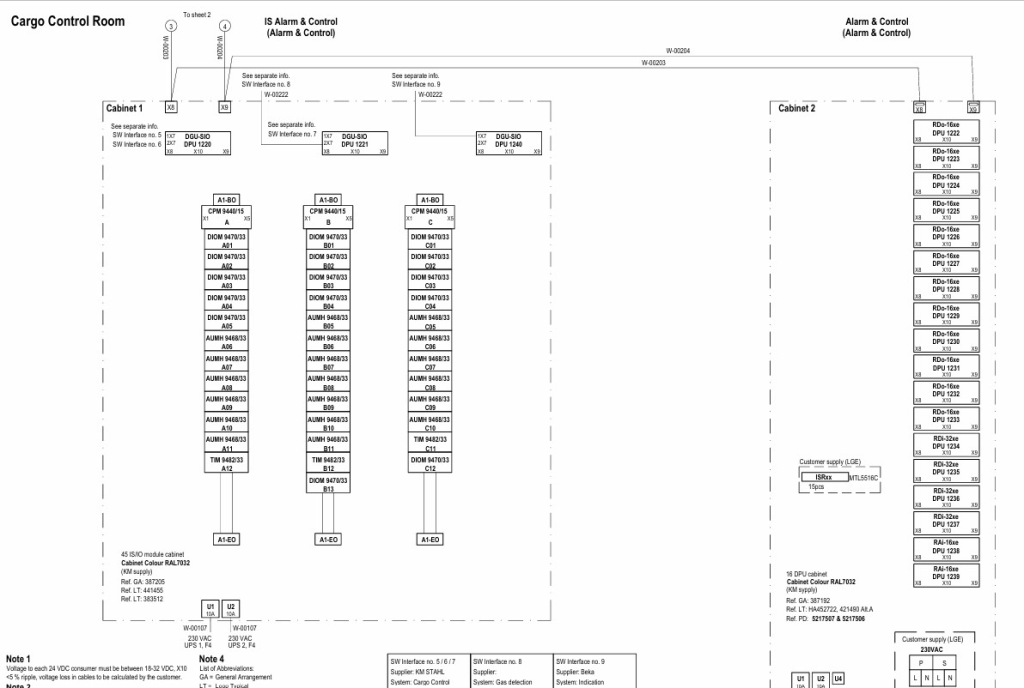

These modules are mainly used to connect with field devices located in hazardous areas. They are installed inside a cabinet, which is commonly called a Field Station.

Not only the devices on deck, but also the machinery and equipment in the Engine Room must be connected to the K-Chief system. For example, cargo pump starters from the Motor Control Station, or hydraulic valve actuators from the Engine Room, can be connected this way.

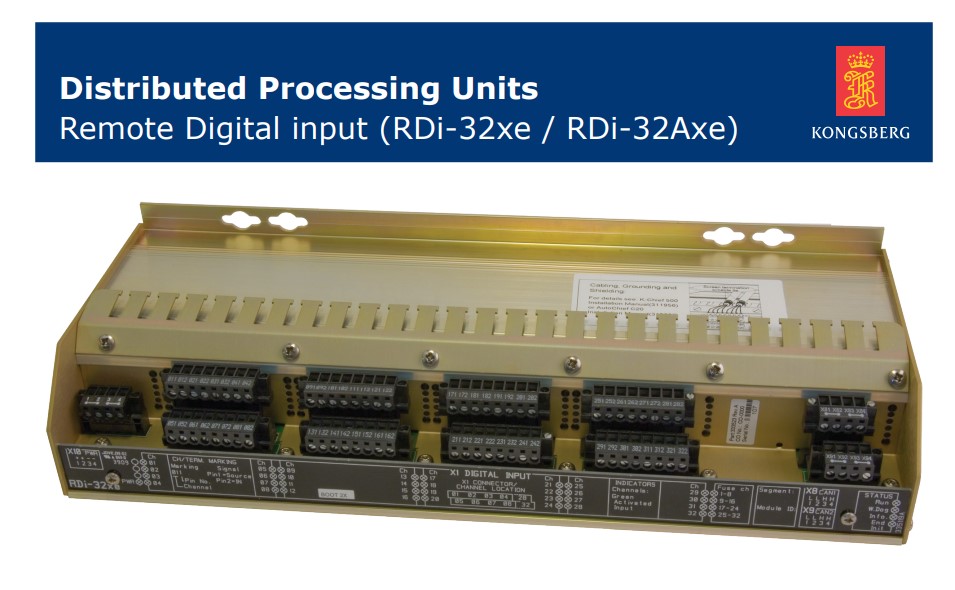

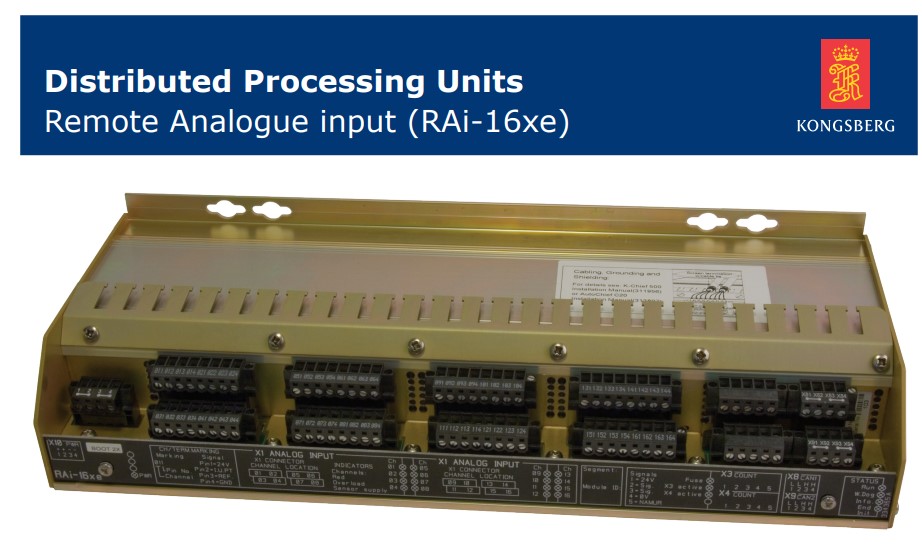

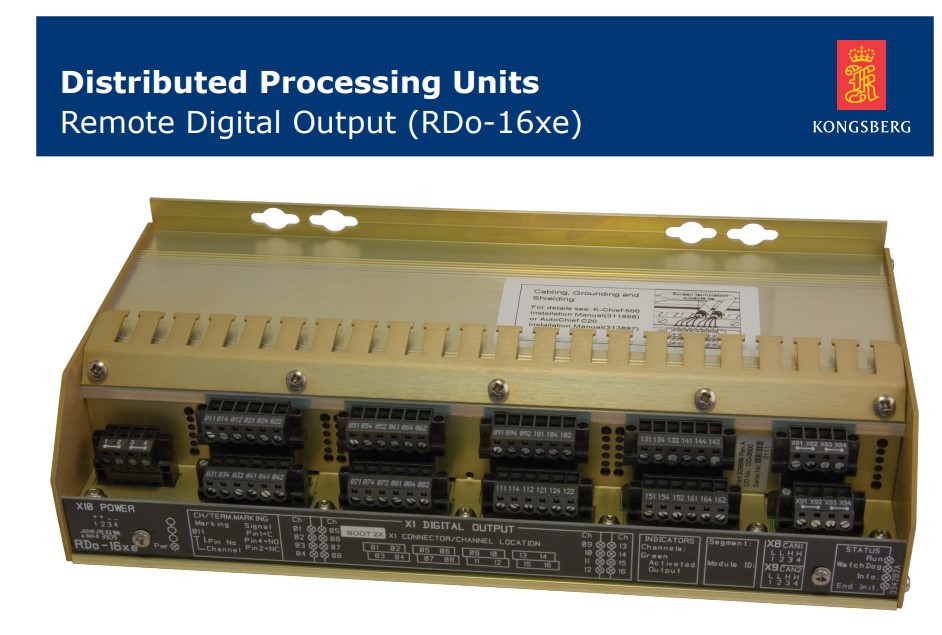

These devices and modules are connected to the Kongsberg Distributed Processing Units (DPU), which include types such as RDI, RDO, RAI, and RAO.

- If the DPU handles Digital Input with 32 channels, it is called RDI32xe (Remote Digital Input 32 channels).

- If it handles Analog Input, it is called RAI-32xe.

- Other DPUs have similar names depending on their signal type and function.

The AUMH, DIOM, and TIM modules all look very similar. Their nameplates and the types of input and output signals they handle are almost the same. They connect with the RS485 bus rail. The CPM module is the main device that collects data and uses the Modbus TCP/IP protocol to communicate with a DGU SIO module. The DPU input and output connect via CAN Bus. It also connects with the DGU SIO.

Modbus TCP/IP is a protocol used to connect control devices via Ethernet networks. Figure 6 shows this clearly. The DIOM, AUMH, and TIM modules connect through CPM 9440/15 A, B, and C. This CPM module is a DGU module like the DPU 1220, 1221, and 1240 series. This DGU module connects via Ethernet cable to the control server PC.

DGU means Digital Governor Unit. Originally, it is used for engine RPM monitoring and control. RS485 and Modbus TCP are used for data processing. This way, the CCR console computer collects sensor data, and the positioners on deck can be started and controlled.

That’s all for this part! I’m breaking this topic into smaller pieces so it’s easier to follow and not too long or boring. In the next part, I’ll share my troubleshooting experience with these modules. Stay tuned!

ETO Kyaw Soe Aung

Leave a comment