K-Chief 600 – Basic Understanding of Input/Output Modules (Based on Real Experience)

Before explaining how input/output modules (I/O) are connected in the K-Chief 600 system, both in hazardous and non-hazardous areas, I’d like to share some background based on my hands-on experience.

I/O modules are foundational to instrumentation systems. So, before connecting or troubleshooting them, it’s essential to first understand how instrumentation works and be able to read circuit diagrams.

For junior ETOs, this is particularly important when starting to work with systems like boilers, refrigeration, generators, etc. Without this understanding, connecting modules carelessly can result in unnecessary downtime or even damage.

Example: Pressure Transmitter and AUMH Module

If you have a pressure transmitter that outputs 4-20 mA for a range of 0-50 bar, it will connect to an analog input channel on an AUMH module.

If the transmitter fails and stops sending current in the 4-20 mA range, the Sensor Fail Alarm will be triggered.

Alternatively, if the AUMH module’s channel itself is damaged, that can also cause a Sensor Fail Alarm. So, both the sensor and the module channel must be considered in troubleshooting.

One useful method is to shift the transmitter signal to another known working analog input channel.

- If the alarm disappears → the original AUMH channel is faulty.

- If the alarm remains → the transmitter is faulty.

This technique helps you isolate whether the issue lies with the module side or the sensor side.

Real Example: Cargo Tank Temperature Transmitter

Let’s say Tank No.3 (Port side) has a temperature transmitter tagged TT-1525, mounted on the tank top. It sends a 4–20 mA signal to the AUMH module, which communicates with the AMS.

If this sensor or its signal path fails, AMS will display:

“TT-1525 Tank 3 Port Temperature Transmitter Fail”

You can trace this tag number in the drawing to find which channel on which module it is connected to.

AMS System and Network Monitoring

In addition to sensor signals, AMS also monitors network and module communication.

In systems like ACONIS and K-Chief, Network Status indicates whether device and module communications are working.

If AMS communication with devices/modules fails, the display won’t update real-time sensor and module statuses.

In Engine Room systems, this is usually well-maintained, but in Cargo Control Room systems (CCR), it’s common to see weak familiarity with AMS.

If AMS data is lost for more than 5 minutes, it’s a sign that the system needs urgent inspection.

Fault Isolation using a 4–20 mA Calibrator

If you use a 4–20 mA signal calibrator and inject a test signal into the input channel:

- If no alarm appears → the sensor was faulty.

- If the alarm remains → the channel on the AUMH module is likely faulty.

(Ensure you know how to set the calibrator in source or sink mode correctly.)

Also, if an analog input channel suddenly reads incorrect values, it could be due to wrong channel assignment. Admin-level access to AMS is required to check and correct this, but it involves risk if done without proper knowledge.

Address Settings in I/O Modules

Each input/output module has its own address. These can be set by rotary switches or DIP switches, depending on the module type.

These modules are typically plug-in types. Be cautious when plugging/unplugging—always switch off the 24V DC supply first.

Sometimes, a channel fault might seem like a module fault. If multiple sensor fail alarms appear suddenly, suspect a module failure. In that case, check:

- Power supply

- Communication cables

- Module status LED indicators

Thermocouple vs PT100 – What’s the Difference?

- Thermocouple sends millivolt (mV) signals

- PT100 sends resistance (Ohm) signals

In your system, a PT100 sensor might be used to measure tank temperature. If temperature rises, Ohm value increases. This is converted to 4-20 mA by a converter and fed into the AUMH module.

If the PT100 or the converter fails, the system will show a Sensor Fail alarm.

Exhaust Gas Temperature Sensors

- Main Engine (ME) exhaust sensors are typically Thermocouples, converted to 4–20 mA and connected to AMS analog input modules.

- Auxiliary Engine (AE) sensors usually go to the engine control unit (ECU), and AMS receives the data via RS-485 serial communication.

Troubleshooting such setups requires both electrical and communication knowledge.

Digital Inputs and Outputs

If a Digital Input (DI) fails, you may not receive pump or fan run feedback signals.

In safety circuits (e.g., pressure or temperature switches), NC (Normally Closed) contacts are commonly used.

A cable short circuit or insulation breakdown can lead to the DI being “closed” even when the switch is open, causing false readings.

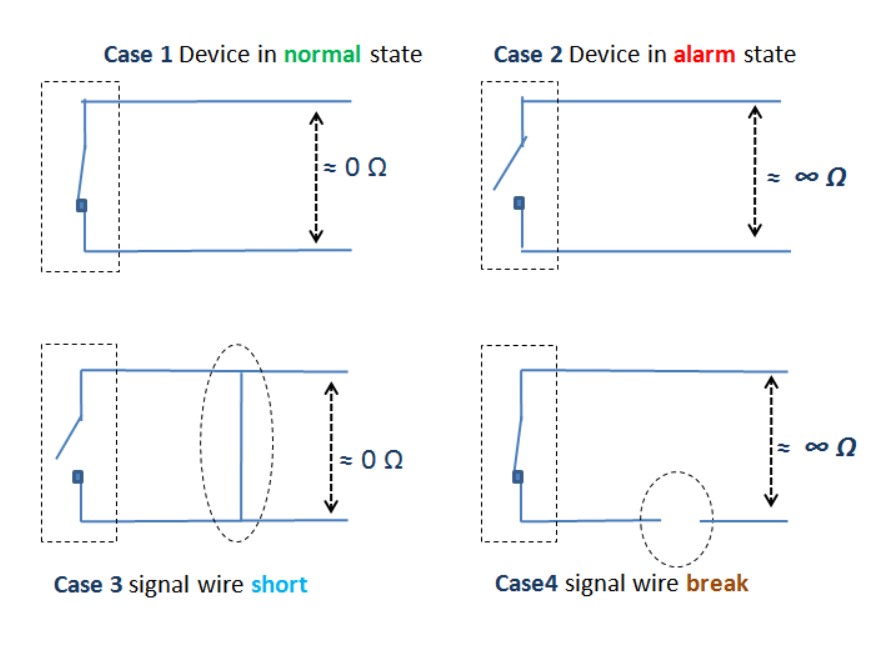

Understanding Digital Input Alarm States (Based on Fig 8)

Before an alarm is triggered, the contact is closed (Case 1). When the alarm state happens, the contact becomes open (Case 2). This change is detected by the digital input module.

However, there is also a Case 3 to consider: if the wiring is short-circuited, the digital input will incorrectly detect the contact as closed even though it should be open. This means the alarm state (which requires the contact to be open) will not trigger as expected.

Similarly, if the wiring is broken or disconnected (open circuit), the digital input will read the contact as open, causing the alarm to trigger.

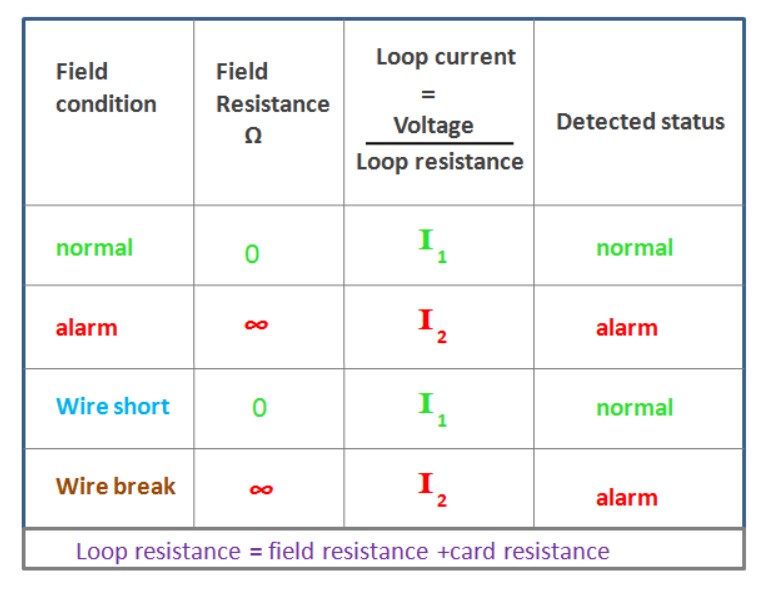

This behaviour is summarised clearly in Table 1.

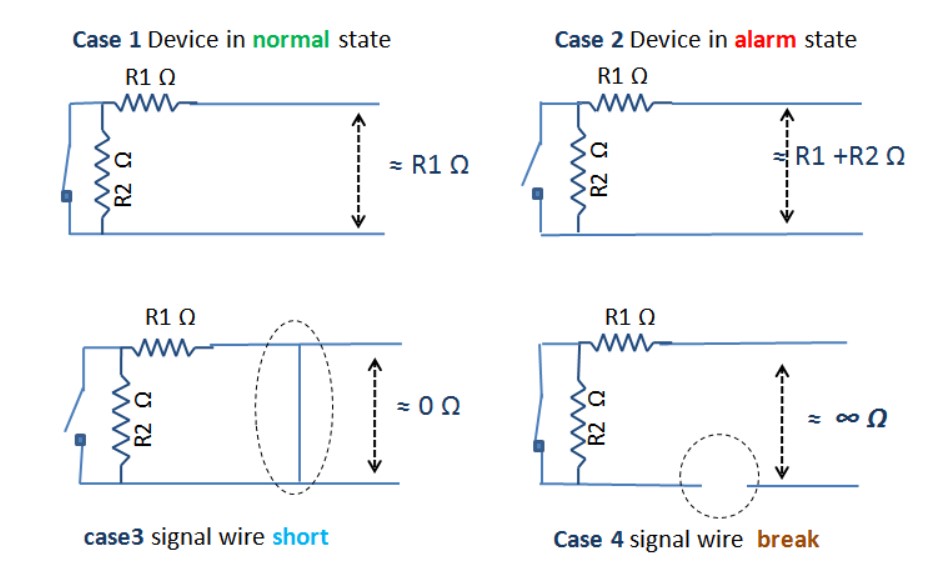

To help detect wiring faults such as shorts or opens, pressure and temperature switches often include line monitoring resistors, as shown in Fig 9.

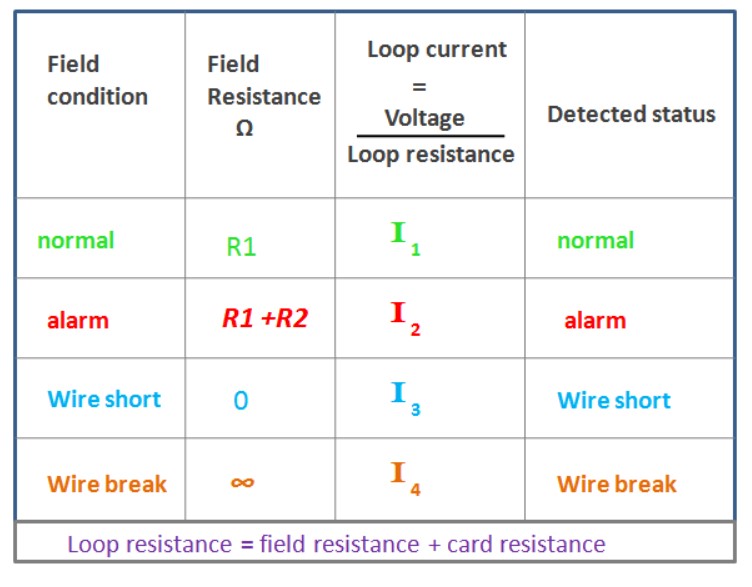

In normal conditions, the digital input module detects the resistance of R1 only. In alarm conditions, the resistance is the sum of R1 + R2.

If a short circuit occurs, the resistance drops to zero, indicating a fault. If the wiring or resistor is disconnected, the resistance reading is abnormal, also triggering an alarm.

These conditions are summarised in Table 2.

Not every digital input module signal is equipped with End-Of-Line (EOL) resistors. Only some important switches, such as the Cargo Compressor LO (Low) Pressure switch, include these resistors to help detect wiring faults.

When a cargo pump is running, the run feedback is taken from a dry contact of the run relay inside the pump starter panel and connected to the digital input module.

- If the relay contact is open (Normally Open – NO), the digital input sees the signal as inactive.

- If the relay contact is closed (Normally Closed – NC), the digital input sees the signal as active.

So, when the pump is actually running, the relay contact should be closed, and the digital input should detect it accordingly.

If the pump is running but the AMS system doesn’t show the run feedback, it’s necessary to check whether the relay contact is properly closed and the signal is reaching the digital input. If not, the issue could be with the wiring or the digital input channel itself.

For digital output signals, the same logic applies. For example, to allow the cargo pump to receive a start-ready digital output signal from the AMS, certain conditions must be met. These may include:

- The cargo discharge valve must be at least 10% open

- Electrical power must be available from the MSB (Main Switchboard)

- Other system-specific interlocks must also be satisfied

Only when all required conditions are fulfilled, the Digital Output from the DIOM (Digital Input Output Module) will be activated to enable the cargo pump starter circuit—often through a Normally Closed (NC) contact.

So, if the cargo pump cannot start even though all the necessary conditions are met—such as the cargo discharge valve is open, power is available, and other interlocks are satisfied—then the first step in troubleshooting should be to check the digital output signal from the AMS that allows the pump to start.

This signal is typically sent through the Digital Output Channel of the DIOM. If this output is not active, the issue may be with the AMS logic, output channel fault, or a missing interlock that is not being detected properly.

By confirming whether the AMS is actually sending the pump start permission signal, you can quickly narrow down whether the problem lies in the control system logic or external wiring/equipment.

Summary

When you see a sensor fail alarm, don’t rush. First, identify whether the issue is on the sensor side or the module side.

Use your knowledge of:

- Circuit diagrams

- Signal types (Ohm, mA, mV)

- Module addresses

- LED indicators

- AMS alarm messages

to troubleshoot accurately.

Always follow safety procedures before testing modules or replacing components. And remember, not all faults are the same—even sister ships may have slight differences in wiring or setup.

Kyaw Soe Aung (2110HR, 23 June 25, Yangon)

Leave a comment