After the previous section in this category, I would like to proceed to examine how the K-Chief system and the cargo pump starter are related. As an ETO, it is essential to know which diagrams or instruction manuals you need to refer to in order to understand the system and effectively troubleshoot any issues.

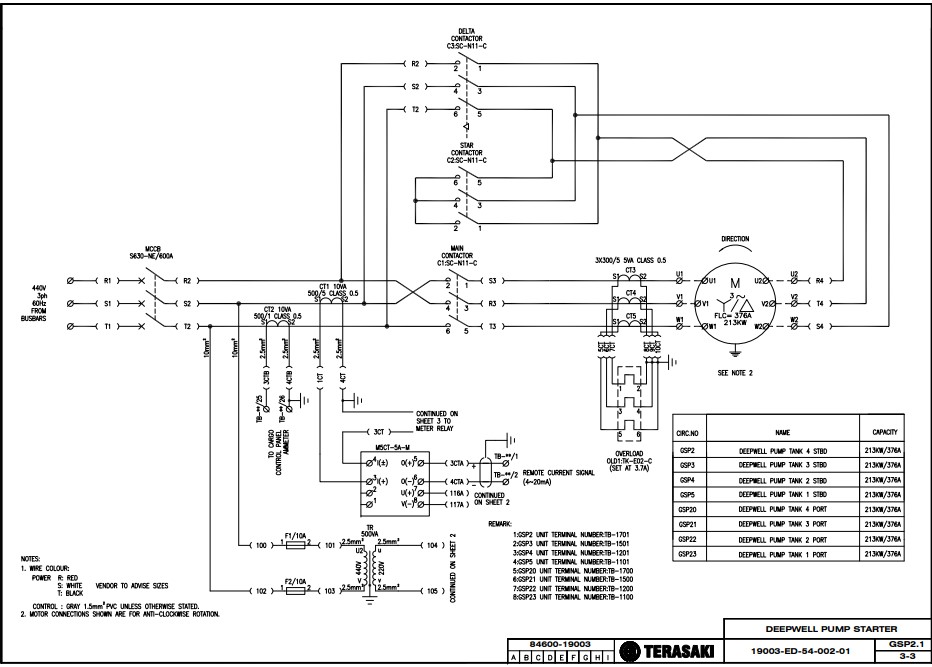

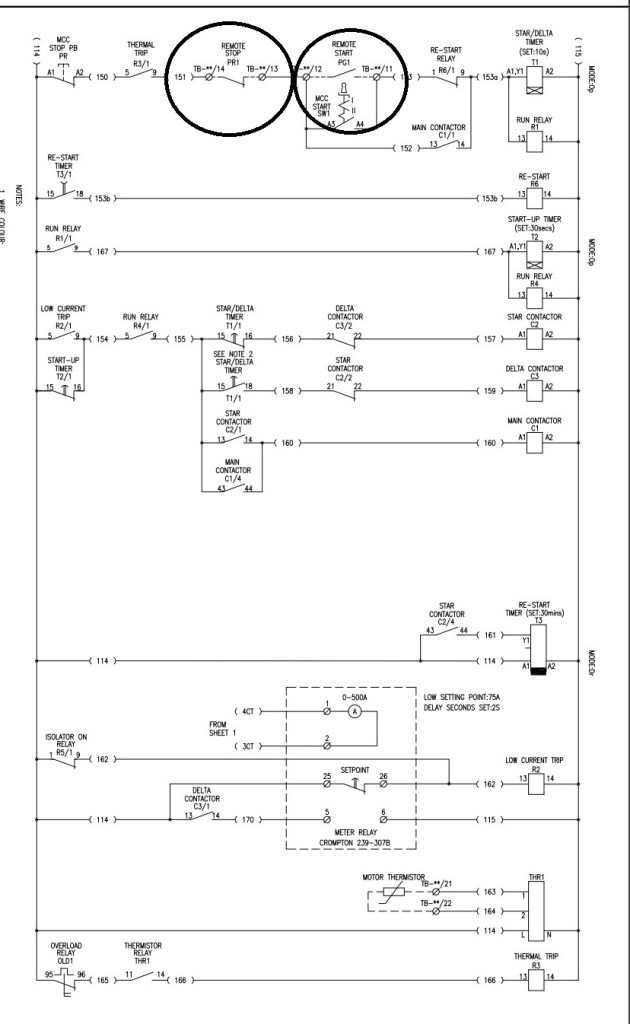

Figures 16 and 17 together illustrate the cargo pump starter circuit diagram. Figure 16 shows the power circuit, which appears to be a star-delta starter configuration, and Figure 17 shows the corresponding control circuit.

In Figure 16, we can see that to start the motor, the Run relay (R1) must be energized. This relay is linked with both Local and Remote Start/Stop controls. You will also notice that in this diagram, there is no direct connection from the K-Chief system.

So, how does the K-Chief start the cargo pump? Actually, the remote start/stop contacts are controlled by the K-Chief system.

In this case, the pump is started from the cargo control system, which means it operates via the remote start/stop function. To do this, the electrical power source must be available, the emergency shutdown system must be off, and all trip points—such as the pump discharge pressure being below 10 bar—must be cleared. Only then will the K-Chief system close the Remote Stop contact (NC), allowing the pump to start. At this point, whether the pump is started locally or from the cargo control system, the pump will run. However, if a trip point is triggered, the K-Chief will open the Remote Stop contact to NO (normally open), stopping the pump.

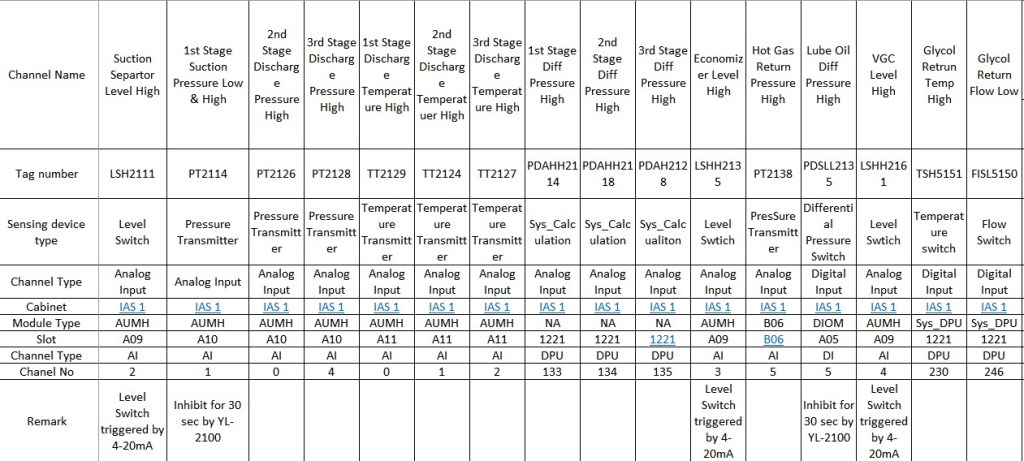

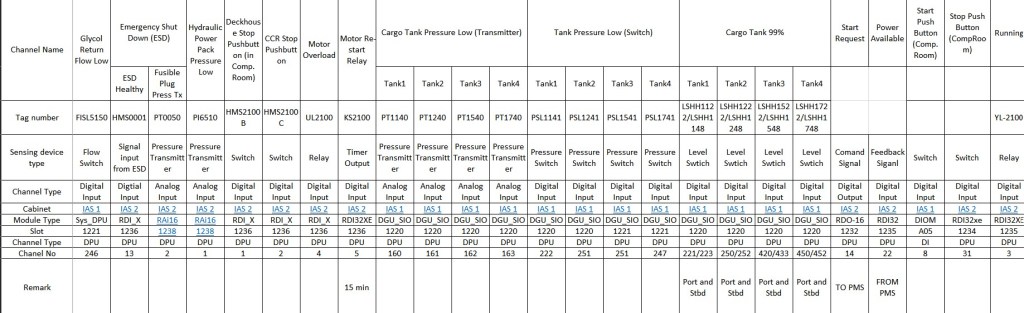

When working with an IAS (Integrated Automation System), it is important to understand the different modules and their structural arrangement. Having a clear grasp of this structure will greatly assist you during troubleshooting.

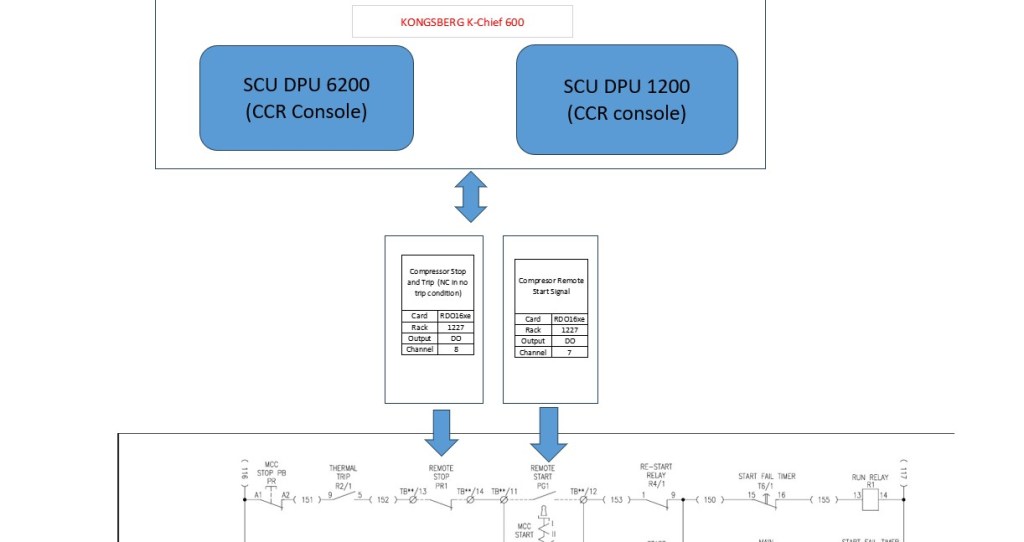

In this cargo pump system, the K-Chief controls the Remote Stop contact by opening or closing it via a digital output. This contact is linked to a digital output module. Since this system is located in a Non-Hazardous Zone, the Remote Digital Output (RDO) Device Protection Unit (DPU) will be used (usually one unit per circuit).

Similarly, the electrical power status is communicated from the Engine Room (ER) through SCU100 and SCU600 units via Ethernet to the K-Chief system. Additionally, the pump discharge valve position is monitored through an analog module connected to the system.

One useful feature of the K-Chief 600 system is the gate function layout, which allows you to see the input conditions required to produce an output. For example, if the cargo pump fails to start and the pump motor starter circuit shows no error, you should check the K-Chief system’s NC stop contact. If the K-Chief NC contact is open, it means the K-Chief is preventing the pump from starting. In this case, you need to inspect the K-Chief panel to identify which interlocks or input criteria have not been met.

What I just explained is based on my own knowledge and understanding, so please consider it as a general guideline. There may be variations depending on different situations, especially when you encounter actual troubleshooting on board.

The ship I am referring to is an LPG carrier equipped with a K-Chief system. It has reliquefaction compressors used to re-liquefy the LPG cargo. These compressors are driven by electric motors, and the starting method employed is an auto-transformer starter. I will not go into detail about the auto-transformer circuit itself; instead, I will focus on how the K-Chief system initiates the starting sequence of the compressor.

Similarly, this is also applicable to the cargo pump. In Figures 18A and 18B, the trip points for the cargo compressor are summarized and clearly shown. Additionally, the relevant signal modules, their locations, and module types are also included in the diagram.

Based on both the input data and the operator’s commands, the K-Chief system controls the Remote Start and Remote Stop contacts by switching them on or off accordingly. This is illustrated in Figure 19.

As mentioned earlier, I am only explaining the part of the motor starting circuit where signals are exchanged between the K-Chief system and the starter. Details related to the compressor control, such as flow control valves or PID actuators, are not included in this explanation.

After the incident I mentioned in Section 4, one of the cargo compressors stopped just a few seconds after starting. A few days earlier, I had also replaced a faulty PID controller for that compressor..

Considering the previous DPU issue and the recent replacement of the PID controller, my initial assumption was that the K-Chief system might still have some remaining fault or was involved in the problem again.

To determine whether the root cause was related to the K-Chief system, I bypassed the contact between TB13 and TB14, as shown in Figure 19. However, after bypassing, the problem still persisted. This confirmed that the issue was not caused by the K-Chief system.

One feature I like about this ship’s starter panel design is the inclusion of a test power supply. When the test power is ON, the main breaker can be opened, allowing the control circuit to be tested independently using the test power supply. This means the motor does not need to start and stop unnecessarily during circuit testing. See Figure 20 for reference.

Since the problem was not caused by the K-Chief system, I proceeded to check the motor starter circuit. I switched off the main breaker and switched on the test power supply. However, I had to continue bypassing TB13 and TB14 because, when testing the motor starter circuit by supplying power only to the control side, the motor will not run even though the related magnetic contactors operate. This means the run signal still reaches the K-Chief system, but since the compressor suction pressure, lube oil pressure, and other parameters are zero (because the compressor isn’t actually running), the K-Chief will trip the compressor. Therefore, it was necessary to maintain the bypass connection during testing.

Using this approach, I tested the starter circuit with both hot check and cold check methods. I discovered that one of the auxiliary contacts on the main magnetic contactor was intermittently loose. This caused the latching to fail, which in turn de-energized the run relay and caused the compressor to stop.

In conclusion, having a solid foundation in instrumentation, the ability to read circuit diagrams, and a basic understanding of module functions are essential. With these skills, troubleshooting AMS/IAS systems can be done more efficiently and effectively.

Reference:

http://www.instrumentaitontools.com

Babcock Cargo Plant Instruction Manual

Babcock Cargo Plant Operating Manual

Leave a comment