Vapour Phase Corrosion Inhibitors (VpCI or VCI) are widely used inside electrical cabinets and panels during storage and transportation. Their primary purpose is to prevent corrosion, especially before marine delivery or long-term storage.

VCI works by releasing vapour-phase particles that form a microscopic protective layer on metal surfaces. This layer isolates the metal from oxygen and moisture, preventing chemical reactions that lead to corrosion. From a mechanical perspective, VCI performs its function effectively.

However, issues begin when VCI materials are left inside panels after delivery.

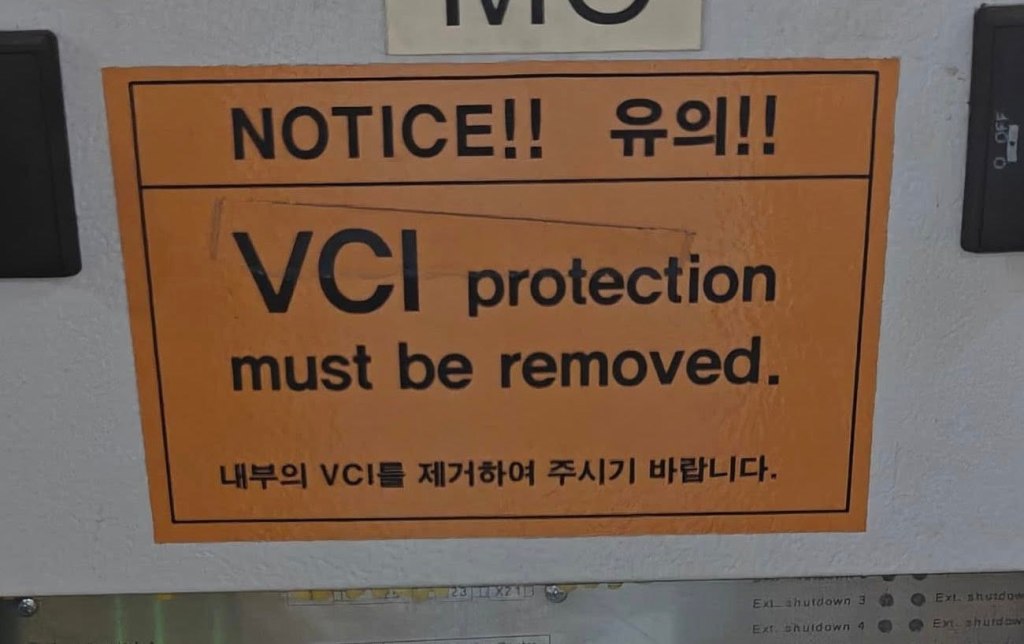

In many cases, panels are supplied with warning labels instructing technicians to remove the VCI protection before the panel is put into normal onboard operation. When this step is overlooked, the VCI material can gradually become a source of contamination rather than protection.

Most VCI products use a paper-based carrier material. Over time, particularly in warm or enclosed environments, this paper deteriorates and breaks down, releasing fine particles. These particles can settle on terminal blocks, connectors, and PCB surfaces.

As contamination accumulates, it can interfere with electronic signals and communication systems. Faults caused by this buildup are often misdiagnosed as moisture-related or hardware failures, making troubleshooting time-consuming and frustrating.

Initially, VCI was mistakenly assumed to be moisture-absorbing protection and was left in the panels. It was only after hearing about a CAN bus failure on another vessel that the real risk became clear.

Key Takeaway

VCI is highly effective for corrosion prevention during storage and transport, but it must be removed before normal onboard use. Leaving VCI materials inside energized electrical panels can result in unexpected communication failures and difficult-to-diagnose electronic issues.

Sometimes, the very things designed to protect our systems end up causing the most unexpected problems.

Leave a comment